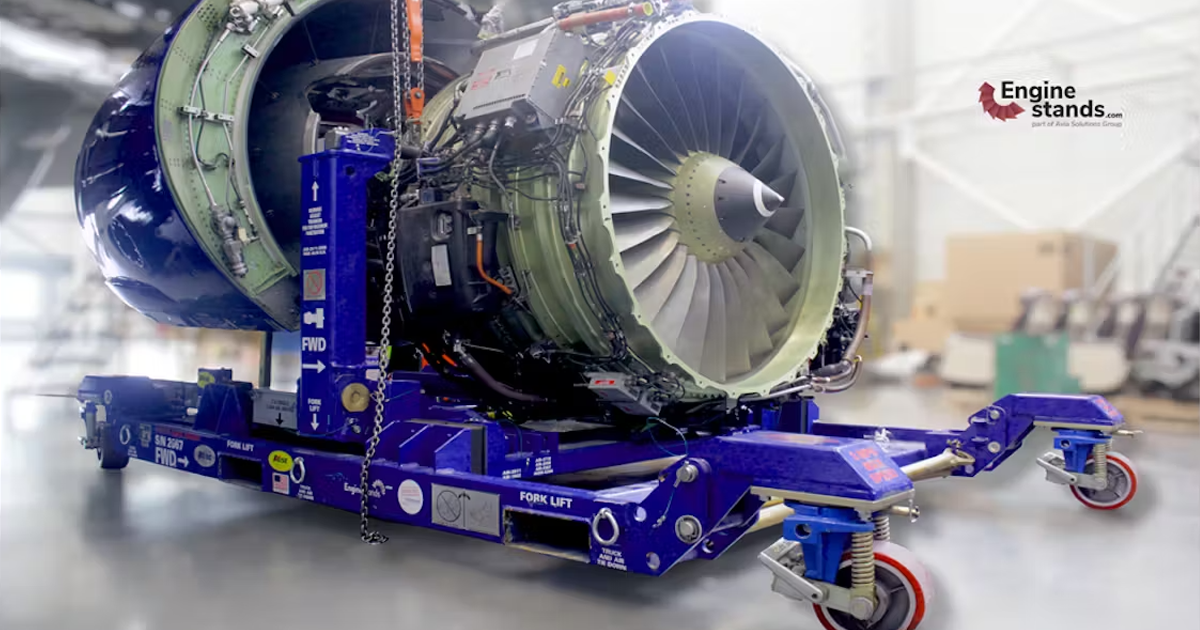

Engine MRO Services

Keep Your Engines Flying Further

End-to-end engine maintenance, repair, and overhaul (MRO) services for Airbus and Boeing fleets. We combine fast turn times, OEM data, and rigorous Part-145 quality to reduce cost per flight hour and maximize dispatch reliability.